Produced Water Management

Designed to enhance water security, sustainability and resiliency, Infinity uses green infrastructure and clean technology to manage the water and wastewater needs of Permian operators in both Texas and New Mexico. By alleviating their dependency on freshwater, and recycling and reusing as much produced water as possible, Infinity is accelerating conservation rates and the pace at which many sustainability goals can be met.

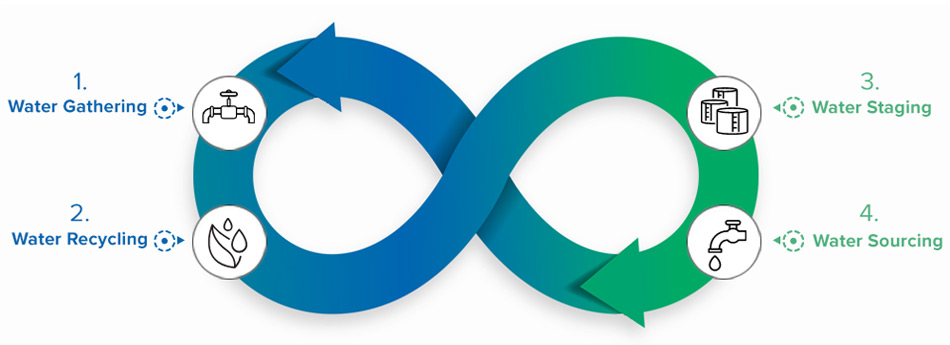

From gathering to sourcing, our midstream solutions result in massive increases in operational and CapEx efficiencies saving operators both time and money.

Water Management Experts

A pioneer in the energy sector, Infinity is reshaping how the industry gathers, recycles, stages and sources (on-demand) water for production.

Using a network of independent, yet connected facilities, we are able to reach a large footprint across the Northern Delaware Basin and deliver water solutions when our customers need them. Equipped with state-of-the-art technology and proven industry efficiencies, each IWS recycling facility is designed to stage record-breaking volumes while also delivering the highest levels of water quality, consistently.

The industry demands a recycled water product that is compatible with the completion system they rely on. At Infinity, we meet or exceed the quality standards and KPIs of each operator’s individual needs.

Our treatment process is engineered to clean the harshest of mixtures addressing the turbidity, pH, TSS and ORP of Permian-produced water. This multi-layered approach not only removes the obvious oil and gas elements from our intake, but also other constituents such as heavy metals, organics and suspended solids that are often amassed.

Curious to learn more? Let's talk KPIs, savings and sustainability today.

Health & Safety

Nothing is more important to us than operational HSE management. At IWS, we take the health and safety of your workers seriously. As a liaison between the water management team and the production team, our operational processes and preparedness plans mitigate vulnerabilities and risks every step of the way. Our goal is to protect your people, assets, and environment.

Meet the Surge with IWS

Working with many of the major operators in the region, Infinity has built a “peer-to-peer” water-sharing network, so there is water sourcing when you need it and gathering when you don’t. Our always-on network, is accessible to all customers, solving timing and logistical issues while also delivering cost savings and measurable environmental benefits.

End Traditional Disposal

As compared to traditional midstream models that rely on the use of disposal wells, our process eliminates the need for injection wells helping operators achieve Net Zero. By conserving and recycling, we’re not only reducing fresh water consumption, we’re mitigating the depletion of this valuable resource, especially in the regions we operate.

Save Big on Water Management

Operators save millions in CapEx by not having to build infrastructure on a facility that is geographically limited to one location. Infinity customers are CapEx light because we incur the cost of building the network for them. When our customer’s rigs change location, our facility connections do, too.